A Case Study on Kenzap Factory Software Integration for Skarda Nams SIA, a Metal Fabricator in Latvia.

Skarda Nams SIA is a metal fabricator based in Riga, Latvia. The factory has specialized in sheet metal fabrication since 1993. Its products include window sills, roofing panels, metal flashings, and rainwater system elements.

One of the factory’s first products was an American-style rainwater system, which became a preferred standard for many newly constructed households in Latvia.

Problem

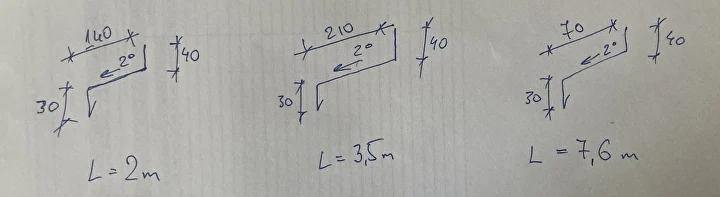

The unique dimensions of the manufactured products make the price estimation process time-consuming and complicated. The process begins with the client, many of whom send handwritten sketch drawings via email or WhatsApp.

These sketches often lack standardization, and estimation managers frequently struggle to understand all the provided details. This results in back-and-forth communication to clarify missing or ambiguous information.

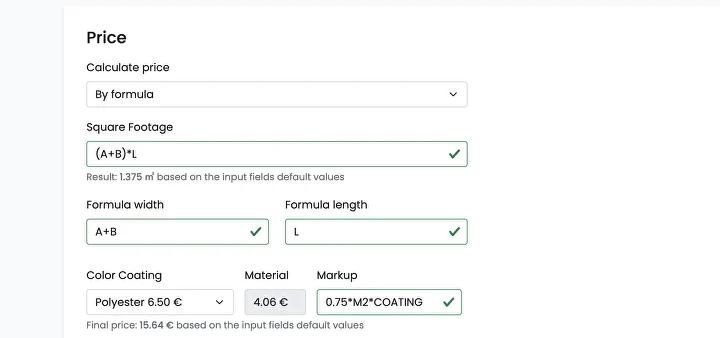

To calculate prices, estimation managers must create a custom equation. First, they factor in the latest price of raw materials. Second, they account for the complexity of the product, which reflects labor costs based on the manufacturing time required.

For the first part of the equation, managers estimate the square footage of the sketch drawing and multiply it by the price of the desired coating type. In the second part, they assess product complexity. For simple cases, this involves a fixed rate multiplied by the number of bends.

For instance, manufacturing a basic window sill requires three metal bends. If the cost per bend is €1, this results in a €3 markup. For complex cases, this requires a consultation with an engineer or a sheet metal worker.

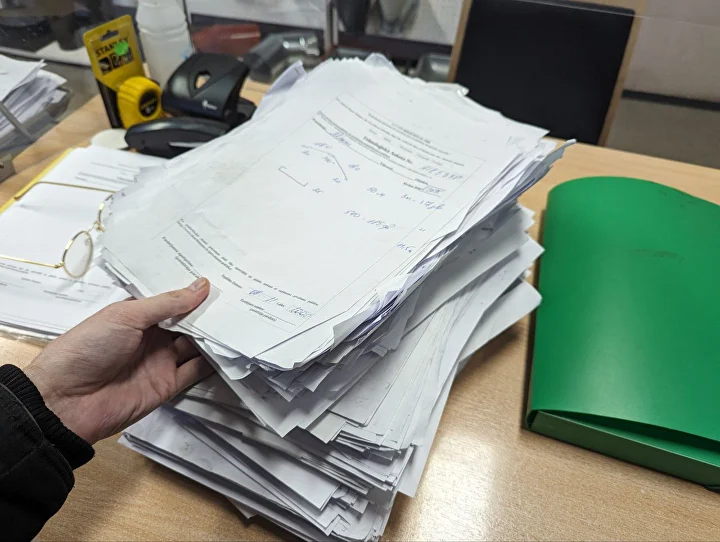

For many product types, managers rely on a product cheat sheet. A cheat sheet is an Excel table of core dimensions used to approximate prices based on two or more key product dimensions. While this speeds up price estimation, the process of sketch mapping and order creation remains highly manual, and price accuracy is prone to errors.

As a result, the manual sketch estimation technique generates thousands of papers sketch drawings archived every year for order reference.

Solution

Various solutions were discussed, including simple WordPress e-store, tablets and specialized software to digitize sketch drawings into the existing CRM. However, the most effective solution proved to be a self-service platform for customers.

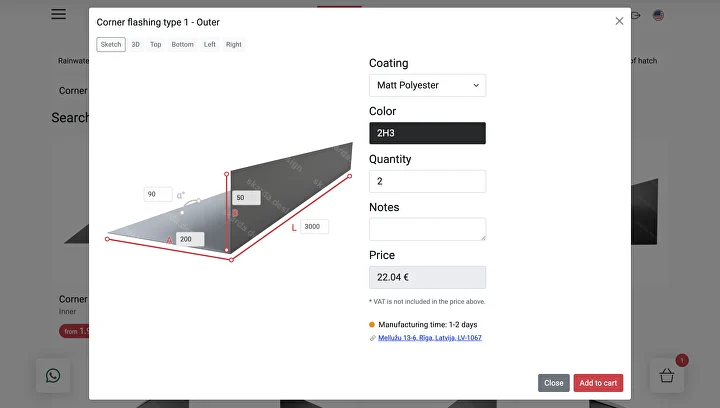

Instead of allowing clients to create their own sketches from scratch, the platform provides a digital library of pre-designed products, eliminating the need for clients to draw anything. With this library, clients can select a product template and input custom dimensions into designated fields, which are positioned over the relevant sides of the product.

These input fields are mapped to an estimation equation, which is defined once in the platform’s dashboard.

As a result, clients can easily estimate the price of popular product types, select desired coating types and colors, and compare prices in real-time. Clients can create quotations and place orders online, even outside of working hours.

The system notifies managers of new orders via email and WhatsApp and synchronizes data with the factory’s existing CRM. This ensures that all orders are reflected in the factory’s primary CRM system.

A self-service platform was launched under a separate brand called Skarda Design and can be previewed here: https://skarda.design/.

Outcome

With the launch of the self-service platform, online orders have become fully digital. Engineers no longer need to manually digitize complex sketch drawings as this step is now automated.

Product price estimations are more accurate and seamless. The platform captures traffic from the old website while also generating new traffic from search engines. Over 80% of platform users are individuals building or renovating homes, and half of the orders are placed outside of working hours.

Within two years of the platform’s launch, the number of individual customers ordering products online grew by 9%. The platform has reduced metal waste and paper usage, and customers no longer need to visit the office to place orders.

Client feedback has revealed new trends in sheet metal fabrication. Clients can be categorized into two groups:

- Advanced Clients: These clients prefer using the new platform exclusively. Their feedback highlights two key advantages: speed and convenience.

- Traditional Clients: These clients are resistant to change and prefer the conventional ordering process, involving office visits and manual sketch drawings.

Trends

As digital tools evolve, so do the technical skills and expectations of clients. Many individuals now take a DIY (do-it-yourself) approach, becoming directly involved in home construction or renovation. For such clients, platforms like Skarda Design allow them to acquire the necessary knowledge and execute tasks independently, eliminating the need for hiring contractors.

Another trend is the growing preference for IT systems over human interaction when placing orders. According to client feedback, they prefer using advanced yet user-friendly interfaces rather than engaging in live communication with humans.

Limitations

While the predefined product library works well for most cases, it cannot accommodate highly personalized requests. For such orders, clients must still communicate with the office directly.

The user journey of every customer is unique. While the input field validation rules prevent customers from entering inadequate sketch dimensions some clients are more prone to making errors than the others. That results in additional step from the management to double check all provided product dimensions directly with the customer prior to making a payment.

Work in Progress

As more user interactions are recorded through the platform, new opportunities emerge to develop a smarter system capable of providing highly personalized assistance with the help of AI. The system could track common errors and offer human-like guidance to enhance user experience.

Another promising improvement is highly realistic product visualization. By applying textures from RAL or RR color catalogs to the product’s 3D CAD model, users can preview exactly how the final product will look before manufacturing begins.

Additionally, some customers have shared feedback requesting a detailed product order lifecycle. This would include updates on key stages, such as when the product is dispatched to production and when it is ready for pickup.

Conclusion

The implementation of a self-service platform at Skarda Nams SIA has transformed the way customers interact with the factory and how orders are processed. By digitizing and automating key aspects of the price estimation and order placement process, the platform has improved efficiency, accuracy, and customer satisfaction.

It has empowered clients, particularly DIY enthusiasts, to take control of their projects while reducing the need for manual sketching and office visits.

Although traditional clients and highly personalized orders still require direct interaction, the platform has set a new standard for convenience and accessibility in the metal fabrication industry. As digital trends and client preferences continue to evolve, the factory is well-positioned to adapt and maintain its competitive edge.

Contact Pavel on LinkedIn or WhatsApp to learn more about this case study.